To understand in-depth how a soldering iron works, it’s important to discuss the purpose of a soldering iron. The role of soldering irons is to supply heat used to melt solder. The melted solder then flows into the joint and joins two workpieces together. Soldering is a common metal joining method. It is popular in electronics, jewelry making, auto repair, and many other applications.

There are several ways to understand how soldering irons work. The first is by analyzing the different components of a soldering iron and their role in the soldering process. The second is by discussing the different types of soldering irons, which generally work differently.

Background: Soldering and Main Components of a Soldering Iron

A soldering iron is meant to melt solder. As a result, the solder is a critical element of any soldering application. Before discussing soldering iron components, it’s important to talk about other elements in the process.

For iron to work properly, it must melt solder, which is composed of metal alloys. Generally, solder contains a high percentage of metals like tin and a small percentage of copper and zinc. While zinc and copper are considered soft metals, tin is also relatively soft. However, it helps to create a stronger workpiece bond.

Flux is also an important component when soldering. As a chemical agent, flux catalyzes the soldering process by aiding heat transfer from the iron to the metals. Many types of solders already have flux in their core. Flux can also be sold separately and added when soldering.

A soldering iron is generally composed of a tip and a handle. There are different soldering iron styles. However, they have a basic purpose. Soldering irons need a heat source which is usually electricity but can be any other heating source. In soldering irons using electricity, current faces high resistance to produce heat.

Generally, electricity doesn’t produce heat when flowing freely. The current buildup is responsible for high electron movement which generates heat. The iron is made to resist electricity flow heating up the soldering tip in the process.

Types of Soldering Irons and How they Work

There are six different types of soldering irons discussed below and how each of them has a different working mechanism. They include;

I. Simple Soldering Iron

This has to be the simplest most common form of soldering irons in the market today powered by electricity. Simple soldering irons are popular in electrical and electronic applications. They are generally low-power, with a rating ranging between 15 – 35 watts. However, higher power ratings are available for providing more heat to enable soldered connections for applications involving metals with higher thermal capacity.

While most simple irons derive their name from simplicity, some are temperature-controlled. It is possible to use such irons to provide fixed temperature, as is the case with soldering stations that are used for more complex applications. Most simple irons have uncontrolled temperatures based on thermal equilibrium. Generally, their temperature decreases when heating a large workpiece.

II. Cordless Soldering Iron

When electricity is unavailable, cordless soldering irons are used. As their name suggests, these types of soldering irons don’t use electricity. Instead, they use other heating sources like gas (butane) or batteries. Cordless irons powered by butane have small butane tanks that can be refilled or exchanged.

Most of these cordless irons have an unregulated operating temperature, with the amount of heat produced by butane-powered cordless soldering irons dependent on the adjustable gas flow. Some of these soldering irons also have interchangeable tips with different sizes for offering some control depending on temperature requirements and other factors like application.

III. Temperature-Controlled Soldering Iron

As the name suggests, this type of soldering iron is advanced with temperature control features. As mentioned above, typical soldering irons have temperature determined through thermal equilibrium and other factors like power input, environment, and materials in question.

When soldering with a simple iron, the temperature drops when the iron is in contact with large workpieces. This temperature drop can compromise the final outcome of a soldered joint. Ideally, small soldering irons shouldn’t solder large workpieces as the final joint is bound to be weak.

That’s where temperature-controlled soldering irons come in. They are more advanced and feature temperature sensors that help to maintain the temperature at precise levels to guarantee a high-quality joint regardless of the size of a workpiece. Temperature-controlled soldering irons come in several types. Some are free-standing, while others have a head, heating element, and tip that is controlled by a soldering station with temperature adjustment, control circuitry, and some displays (in special instances).

Temperature-controlled soldering irons work by controlling soldering temperature. This can happen in many ways. For instance, it can be through variable power control (such as with a light dimmer) where the equilibrium temperature changes without automatic measurement or regulation of temperature.

The soldering irons can also use thermostats usually installed in the tip to automatically power the element on/off. Thermal sensors may be used alongside thermostats. These sensors (commonly known as thermocouples) feature circuitry for monitoring soldering iron tip temperature and adjusting power accordingly. Some advanced models may have software that can be modified to offer more precise soldering.

Some temperature-controlled soldering irons also feature magnetized soldering tips that gain or lose magnetic properties based on temperature. They feature magnetic tips that are close or open power supply to a heating element. When the temperature exceeds a certain pre-determined level, power is cut off, dropping the temperature to levels that allow restoration of magnetism.

IV. Soldering Station

Soldering stations work with the aid of temperature controls. They consist of an electrical power supply, control circuitry, user temperature adjustments, displays, and a soldering iron/head featuring a temperature sensor at the tip. Soldering stations have a stand where hot irons are placed when they are not in use. The stand can also house cleaning aids. Soldering stations are common in electronic applications.

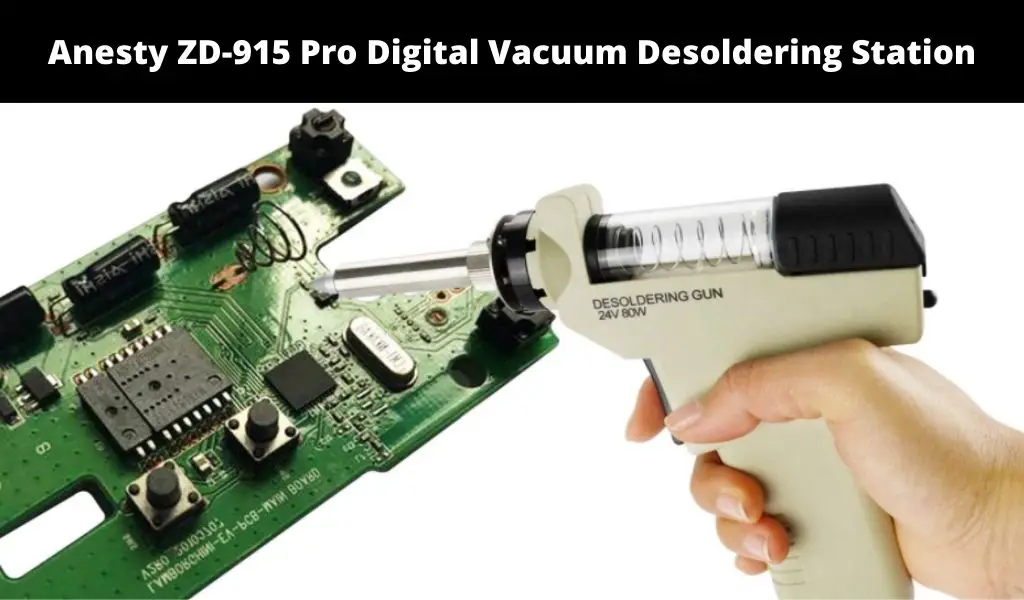

V. Soldering Tweezers

Soldering tweezers work differently than a typical soldering iron. They are also used for different applications (mostly small soldering/desoldering applications). Soldering tweezers are common when working on terminals, links, capacitors, resistors, diodes, etc. These types of soldering irons can be free-standing or used from soldering stations.

They work like tweezers. The only major difference is the tweezers have heated tips on arms that can be separated easily or used to apply gentle force. Soldering tweezers work by melting soldered joints in precise places. The resulting components are removed using a vacuum or picked using tweezers.

Other Types of Soldering Irons and How they Work

A hot knife also qualifies as a type of soldering iron that looks like a knife (features a double-edged blade) attached to a heating element. Hot knives can reach 538 degrees Celsius, allowing them to work in many soldering applications. They work as typical knives i.e., cutting through soldered joints.

Summary: How Does a Soldering Iron Work?

There may be many types of soldering irons. However, they all work on similar principles. Generally, they must have a heat source which is usually electricity, batteries, or butane. They also need a tip that heats up and melts the solder. The different types of irons work around this basic principle. If you want a soldering iron for basic applications, a simple soldering iron will work perfectly. Otherwise, you may need to think of more advanced soldering irons that allow you to control the temperature or those that work anywhere.

FAQs About Soldering Irons and How They Work

What are the ideal types of soldering irons?

It depends. The best soldering iron will be determined by the application at hand. In typical home soldering applications, a simple soldering iron may be the best choice. However, complex soldering involving large workpieces may require sophisticated soldering irons with temperature control features. To get the best outcome, start by considering your application and then do your research. Luckily, there are soldering irons perfect for just about any application thinkable.

How to Use a Soldering Iron?

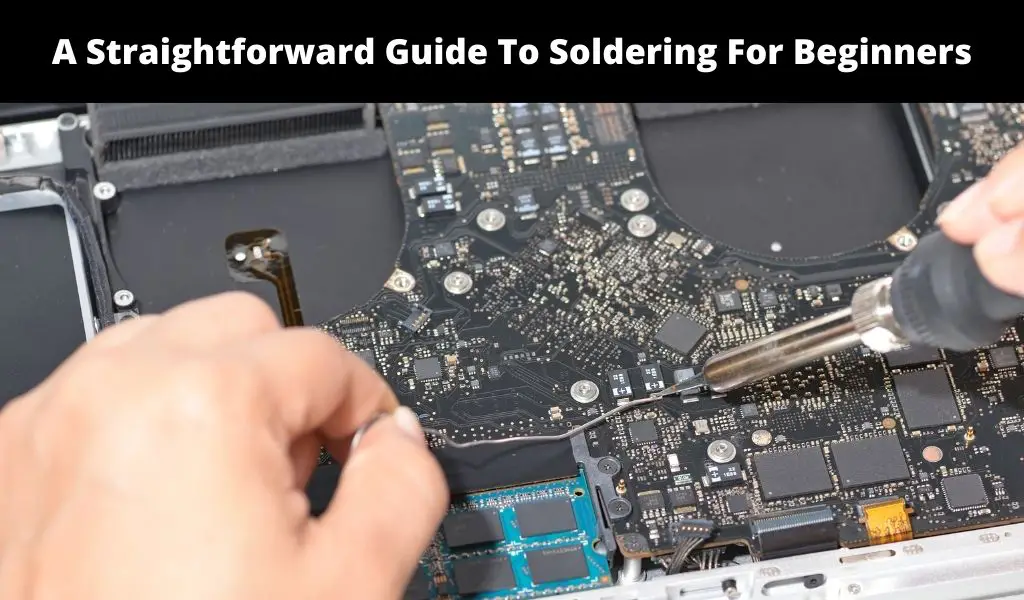

Selecting the best type of soldering iron doesn’t mean much if you don’t know how to use a soldering iron properly. Soldering should begin with understanding the temperature requirements for your project. The materials being soldered together should dictate the temperature requirements. The solder in use should also be considered. The best soldering iron is the one that supplies enough temperature for the application at hand. Also, the soldering iron shouldn’t burn components or produce heat that makes soldering impossible.

Once you have the perfect soldering iron, soldering is easy. Provided the soldering iron is clean and free of residue, soldering is as simple as waiting for the tip to be hot enough. It also matters how you hold the iron. Generally, you should hold the iron to allow molten solder to flow directly into the joint. The workpieces should also be secured in place before and during the soldering process. There should also be ample time for cooling. Most importantly, soldering irons should be cleaned after use and stored as directed.